Ladder example

While searching for an alternative hunting load for my .308, I tried the product of a local bullet manufacturer. I like using Sonchem S335 gunpowder and the bullet weight is 165gr. Should this have been the first time that I used 165gr bullets in my rifle, I would have started at the closest bullet weight recommended by the gunpowder manufacturer (168gr) and I would have started at a load of 37.4gr and worked up to 41.5gr in 0,3gr increments. However, it has become clear to me over time that the best load for my rifle is between 40gr and 41,6gr for 165gr bullets. I decided to explain this specific example since fewer shots were fired, but more than one potential sweet spot materialised visually. Under normal circumstances it remains of the utmost importance to start shooting at the minimum load and to gradually work up to the maximum load. Look out for any signs of pressure and do not fire a higher load should any signs of pressure be experienced.

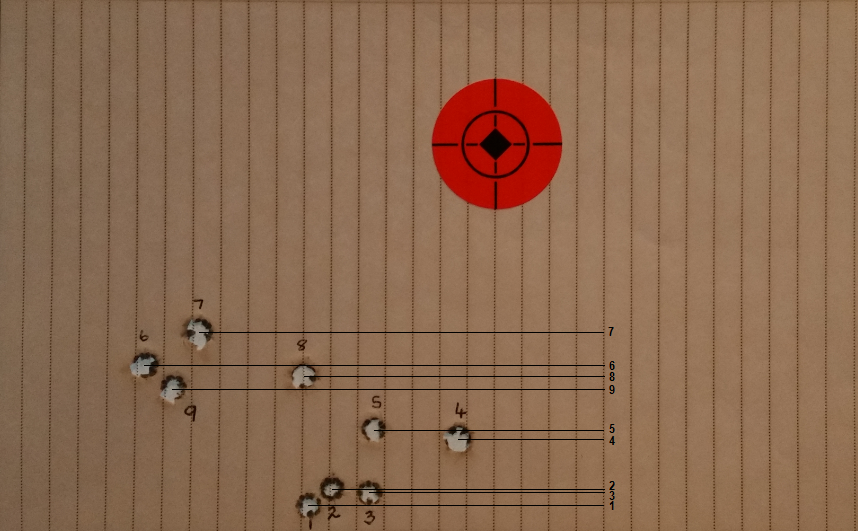

The ladder was shot at 200m and every shot was aimed at the orange circle in Figure 1. The vertical distribution indicates that shots 1, 2 and 3 form a bundle and then potentially again shots 4 and 5, after which the larger bundle is formed by shots 6, 7, 8 and 9.

Please note that the shots will not necessarily bundle in numerical order and that shots of different loads can bundle in a back-and- forth manner. It is more sensible, however, to choose group loads from shots of successive loads forming a bundle, since it would indicate that successive loads are stable and that such shots form a bundle. However, according to the original theory, the centre shot in the bundle should be chosen and loading should be done around this load to shoot groups.

Selecting this group test load which forms part of the bundle is not normally easy and it requires a lot of experience and interpretation. It compelled me to establish an identification process for this group test load. I originally thought that when shots bundle, there should be some or other constant or minimum variation in the speed of each of the shots. Fortunately I normally shoot over a chronograph, which enabled me to compare the speed of the different loads with a view to identifying some or other trend. After having tested a number of calculations, a specific trend was identified, which concurred with the previous ladder results. The calculation can be aligned with the concept of Absolute Minima and Maxima in Calculus mathematics. The application is quite simple in the case of load development and can be explained as follows on the basis of the above ladder test.

Absolute Minima calculation

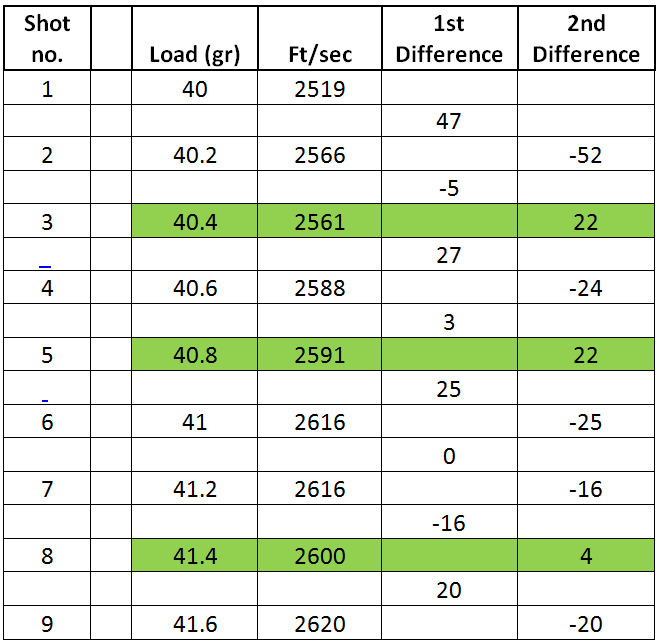

Table 1 reflects the calculation for the ladder test as reflected in Figure 1. The calculations were done by using Microsoft Excel and are explained in order to be able to repeat the calculations. The manner in which it is reflected in Table 1 makes it easier to immediately identify the relevant load.

Table 1: Absolute Minima calculation

The first step in this calculation is to enter the load and the speed of each load (usually in foot per second), from the minimum to the maximum load, on the spreadsheet. The difference in speed between the different loads is then calculated in the 1st Difference-column. The value of 47 is only (2566 – 2519) and -5 is (2561 – 2566). The rest of the values in the 1st Difference-column are calculated in the same manner. In the 2nd Difference-column the process is repeated and the difference of the difference in speed is calculated. The value -52 is only ((-5) – ABS(47)). Die ABS before the value to be deducted is an Excel function and merely means that the absolute value or positive value of the number must be deducted and that the sign in front of the figure must not be taken into account. On the same basis the value of 22 will be (27 – ABS(-5)). The rest of the values in column 2 are calculated accordingly.

After such calculations a trend is usually reflected in the 2nd Difference-column, which reflects the values from top to bottom in a negative-positive-negative pattern. There are three such cases in this specific example. The positive value of absolute minima of the trend can be traced to a specific shot number or load as indicated by the green lines. The first case is (-52 / 22 / -24) with a positive value of 22, which agrees with shot 3 or 40.4gr. The second case is (-24 / 22 / -25) with a positive value of 22, which agrees with shot 5 or 40.8gr. The third case is (-16 / 4 / -20) with a positive value of 4, which agrees with shot 8 or 41.4gr. Interestingly each of the loads identified by using the Absolute Minima method can be linked to a shot in the visual ladder bundles reflected in Figure 1.

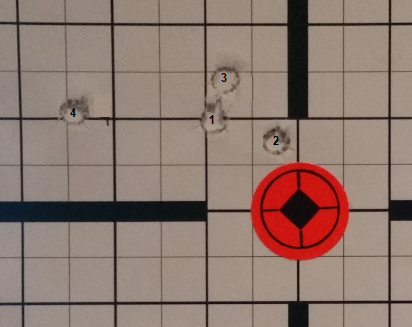

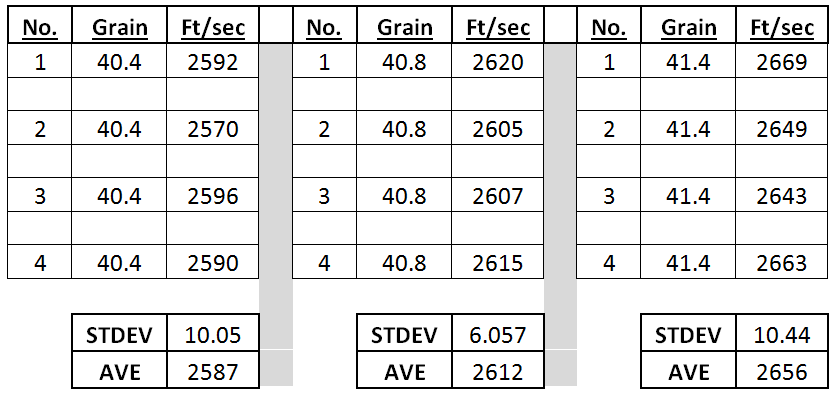

Based on this confirmation I decided to load shots 3, 5 and 8 as group tests. Four rounds of shot 3 (40.4gr), shot 5 (40.8gr) and shot 8 (41.4gr) were loaded and shot at 200m. The results of these group tests are reflected in the figures below:

Figure 2

Figure 3

Figure 4

The speed results of the shots are listed below in Table 2. In the end I decided on a load of 40.8gr since the horizontal and vertical distribution between the shots were significantly smaller than the other two and since the standard deviation (Stdev) of the speed between the rounds of the same load was the smallest. Later on I again tested the 40.7gr, 40.8gr and 40.9gr groups to confirm that 40.8gr was in fact the better load for this combination in my rifle.

Table 2: Speed and variance of grouping tests

How do I use a combination of the ladder and Absolute Minima method?

The most important principle is "do the one and don't neglect the other". It is of the utmost importance for a shot to shoot over a chronograph during load development in order to interpret the visual ladder and the Absolute Minima calculation jointly and separately. The node or stable point which is determined by the Absolute Minima method indicates a load where the speed variation of the load concerned will probably be stable or minimised. The best results are usually obtained when the visual ladder forms a bundle and when the Absolute Minima method identifies a load which forms part of the bundle. Should more than one corresponding load be identified, it would be advisable to test both in order to identify the better load whereafter loads of 0.1gr on both sides of the most stable load can be tested.

General remarks

Remember that safe and responsible reloading practices must always enjoy preference. Be on the lookout for any signs of pressure and stop immediately should any signs of pressure be experienced. Always choose accuracy above speed during load development. Make sure of your shooting technique and make sure that the gun rest is stable to ensure that the rifle is placed in the same position every time before a shot is fired. Each and every rifle has its own recipe and it is important to determine an optimal load for your rifle by means of a structured process. Aside from all the possible "shortcuts" which will get to an accurate load with fewer shots, it is unavoidable for any reloader to spend time on the shooting range. Eventually it becomes difficult to decide whether a reloader shoots better groups due to an optimal load for his rifle or due to the time he spends on the shooting range, refining the art of accurate shooting. I sincerely hope that the methods explained will assist you, as co-reloader, to achieve the accuracy potential of your rifle.